سفارشی سایر قسمت های مهر دیگر شامل انتخاب مادی، طراحی بخش و تکنیک های تولید شده که به نیازهای پروژه منحصر به فرد می باشد. با همکاري با توليد کننده هاي تجربه مشتري ها ميتونن مشخصات دقيقي به دست بيارن و در صنایع و پروژه های متفاوتی در صنایع و پروژه های گوناگون را بررسی کنید.

در مقايسه با مکعب فلز معمولي، برق دقت لازمه شرايط سخت تري

مرگ مُردن دقیق باید بسیار دقیق طراحی شده باشد که اغلب نیاز به درمان دقیق سطحی سطحی دارد. مُرده بايد مقاومت لباس خوبي داشته باشه

شرایط کیفیت سطح برای مواد دقیق بسیار بلند است. مقادیر مادی باید درست و ثابت باشد، و سطح معمولاً لازم است که سطح نرم، بدون خراش و بی نقص باشد. برای فلز، استریپ یا مواد خام، عرض مادی باید در محدوده تحمل مشخص شده باشد. مواد مشترک مورد استفاده قرار گرفتن دقیق شامل فولاد بی لکن، آلیای آلومینیوم، آلیاژی مس و غیره.

برای مبارزه ی فلز دقیق، طراحی و تولید خوب و همچنین کنترل سخت کیفیت مادی، برای مطمئن شدن کیفیت محصول ثابت در تولید بزرگ ضروری است.

مزایای استفاده از قطعات های دیگر عبارتند از بسیاری مادی، ویژگی های ترتیب شده و طراحی های برنامه های خاصی است. این مولفه ها نوآوری ها را در سراسر صنایع مختلف قابل افزایش می دهند و در مورد نیازهای منحصر به فرد با عملکردی، پایداری و تولید هزینه موثر، موفقیت پروژه های گوناگون

مکعب فلز دقیق یک روش تشکیل سرد است، و شامل نُه عملیات پردازش است:

خالي توي حفره کپک گذاشته شده و فشار برای خارج کردن آن از شکاف جمعی برای تشکیل دادن قسمت های خالی یا جامد استفاده می شود.

چرخش: انتهای فلز برگه در یک سر گرد نزدیک بود که معمولاً برای پردازش قطعه هایی شبیه کوه ها استفاده می شود.

نقاشی: فلز برگه به قسمت های خالی از هر شکلی فشار داده می شود با استفاده از یک مرگ، یا بیشتر از قطعه های خالی فشرده می شود.

خم شدن: فلز برگه ها با زاویه خاصی با استفاده از مرگ، یا دوباره برای قطعه های قبلی قطع می شود.

سوراخ ها یا لبه های خارجی فلز با استفاده از مرگ به دیوارهای مستقیم تبدیل می شوند.

انبوه: نیروی رادیویی به قسمت خالی توسط یک مرگ برای گسترش قطر محلی استفاده می شود.

فشار رادیویی به دهان قسمت خالی توسط یک مرگ از بیرون به درونی استفاده میشه کاهش قطر محلي

گسترش: روش تغییری که ابعاد شعاعی یک خالی خالی یا لوله ای در یک مکان خاص را بزرگ می کند.

تکه کردن: تخت کردن سطح نابرابر کار ؛ فشار کار کاری که قبلاً خم شده یا کشیده شده در شکل درست است.

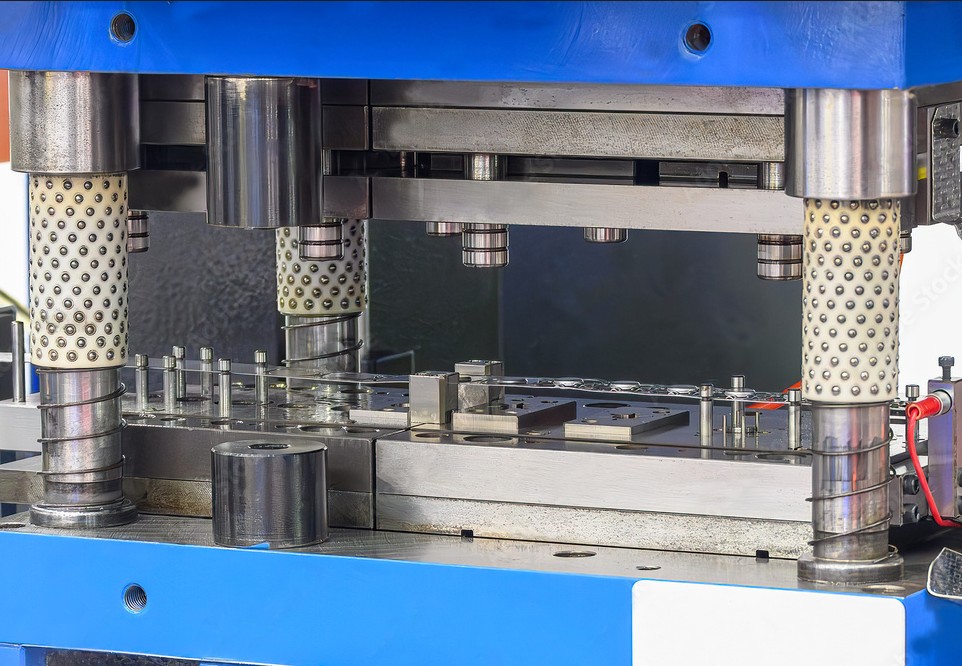

تجهيزات مورد استفاده براي مُردن شامل فشار هاي دستي، فشار هاي مکانيکي، فشار هاي هيدروليک، فشار هاي شنوايي فشارهای مکانیکی سرعت بالا، فشار های سی ان ای و فشار دقیق

مولفه های مثبت دقیق به طور گسترده در سراسر صنایع مختلف استفاده می شوند، و درگیری HHC به افزایش یافته است، اما محدود نیست، بخشهای زیر:

صنعت خودرویی: مولفه های مکعب دقیق در تولید بخش های مختلف در اتومبیل از جمله ساختار بدن، صندلی ها، موتورها، استفاده می شوند. سيستم تعليق و سيستم هاي انتقال

صنعت الکترونیک: مولفه های مثبت برای تولید بسته ها، اتصال ها، سینک های گرمایی استفاده می شوند و اجزاي ترک کننده در محصولات الکترونيک

صنعت الکتریکی: مولفه های دقیق در تولید ترمینال ها، بلوک های پایانه، سوئیچ ها، و سوکت براي تجهيزات الکتريکي.

صنعت تماس ارتباطی: مولفه های دقیق برای تولید اجزای بحرانی مثل آنتن ها، اتصال و محافظت از محافظت در تجهيزات ارتباطي

وسایل پزشکیاجزای مکعب دقیق در دستگاه های پزشکی برای تولید بسته ها، قسمت های ابزار، کاته ها و اتصال ها مورد استفاده قرار می گیرند.

صنعت انرژی جدید: اجزای دقیق نقش بسیار مهمی را داردبخش هایی مثل ماشین های انرژی جدید، فوتوولتیک و انرژی باد، که برای تولید مواد باطری، پنل های خورشیدی استفاده میشه و قسمت هاي توربين باد

وسایل خانه: مولفه های مکعب دقیقه در وسایل خانه برای ساخت ساختن خانه ها، دکمه ها، سوئیچ ها، استفاده می شوند. و قسمت هاي موتوري

صنعت هوایی فضایی: مولفه های مکعب دقیق در بخش هوا فضایی برای تولید ساختار هواپیما، قسمت های موتور و اجزای فضایی استفاده می شوند.

زیر مزایای خدماتی که ما برای مواد مخالف فلز دقیق سفارش میدیم

پشتیبانی طراحی مهندسی: ما یک تیم مهندسی با تجربه داریم که می تواند پشتیبانی طراحی حرفه ای را برای بهینه سازی طراحی محصولات کمک کند و هزینه های مشتری هامون رو کاهش میده

تولید سفارشی شده: ما می توانیم اجزای فلز دقیق رو طبق شرایط مشتری که شامل ابعاد، شکل ها، مواد، درمان سطحی و غیره تا به نيازهاي شخصي برسيم

وسایل تولید پیشرفتهما تجهیزات پیشرفته و دستگاه ماشینی داریم، از جمله فشارهای سرعتی، فشار های سی ان این و غیره که ما رو قادر به دست آوردن کارآمد و قابل تحقيقات بالايي

کنترل کیفیت سخت: ما یک سیستم مدیریت کیفیت ابتدایی ایجاد کرده ایم که تمام مرحله ها از دریافت ماده خام تا کنترل فرایند تولید و بازرسی نهایی محصول رو پوشش میده ...... این اطمینان دارد کیفیت محصول پایدار و قابل اعتماد.

قابلیت تولید انعطافی: ما توانايي هاي توليدي انعطاف پذير داريم و مي تونيم سريع توليد طبق اندازه ي نظم مشتري ها رو تنظيم کنيم تقاضا داره

خدمات وسیع پس از فروشی: ما خدمات کامل پس از فروش را فراهم می کنیم، از جمله راهنمایی های استفاده از محصول، پشتیبانی فنی، و نگهداری پس از فروش، برای مطمئن شدن هر مشکلی که با مشتری ها در زمان استفاده از محصولات مواجه می شوند، می تواند بلافاصله روبرو شود.

با این مزایای خدمات، ما متعهد هستیم که مشتریان مولفه های مکمل فلز دقیق عملکردی بالا، بهشون کمک میکنه تا ابداع محصولات و رقابتی در بازار افزایش بدن